Thimbles, Formerly DIN3090

Key words:

DIN3090

Thimbles, Formerly DIN3090

Classification:

Product Description

|

Specification |

Weight |

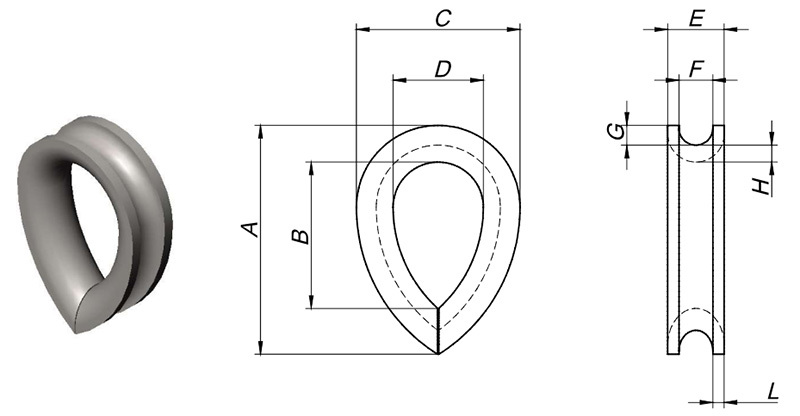

A |

B |

C |

D |

E |

F |

G |

H |

L |

|

Kg |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|

|

4*5mm |

0.01 |

32 |

20 |

20 |

10 |

7.5 |

5 |

2.5 |

2.5 |

1.25 |

|

6*7mm |

0.028 |

47 |

31 |

29 |

15 |

10 |

7 |

4.2 |

3 |

1.5 |

|

8*9mm |

0.065 |

64 |

40 |

41 |

20 |

13 |

9 |

6 |

4.5 |

2.2 |

|

10*11mm |

0.125 |

78 |

50 |

53 |

25 |

16 |

11 |

7.5 |

5.5 |

2.5 |

|

12*13mm |

0.235 |

98 |

64 |

60 |

30 |

19.5 |

13 |

11 |

6 |

3.25 |

|

14*16mm |

0.245 |

110 |

70 |

69 |

35 |

21.5 |

16.5 |

8 |

8 |

2.5 |

|

16*18mm |

0.39 |

126 |

81 |

78 |

40 |

24 |

18 |

10.5 |

8.5 |

3 |

|

18*20mm |

0.485 |

140 |

94 |

88 |

45 |

27 |

20 |

9.5 |

9 |

3.5 |

|

20*22mm |

0.78 |

150 |

100 |

100 |

50 |

31.5 |

23 |

13 |

101 |

4.25 |

|

22*24mm |

0.89 |

162 |

109 |

102 |

55 |

32 |

24 |

14 |

10 |

4 |

|

24*26mm |

1 |

175 |

121 |

110 |

60 |

34 |

26 |

15 |

10 |

4 |

|

26*29mm |

1.58 |

195 |

130 |

122 |

65 |

42 |

33 |

16.5 |

13 |

4.5 |

|

28*31mm |

1.685 |

215 |

147 |

130 |

70 |

43 |

35 |

17.5 |

12.5 |

4 |

|

32*35mm |

2.28 |

235 |

163 |

145 |

80 |

48 |

36 |

17 |

14 |

6 |

|

36*40mm |

3.58 |

270 |

185 |

165 |

90 |

54 |

41 |

21 |

17 |

6.5 |

|

40*44mm |

6.38 |

330 |

205 |

200 |

100 |

61 |

47 |

30 |

20 |

7 |

|

44*48mm |

8.2 |

350 |

224 |

220 |

110 |

66 |

52 |

33 |

22 |

7 |

|

48*53mm |

8.8 |

370 |

244 |

230 |

120 |

72 |

57 |

34 |

23 |

7.5 |

|

52*57mm |

12.2 |

410 |

280 |

250 |

130 |

80 |

63 |

34 |

25 |

8.5 |

|

60*66mm |

19.4 |

490 |

330 |

295 |

150 |

89 |

70 |

40 |

25 |

9.5 |

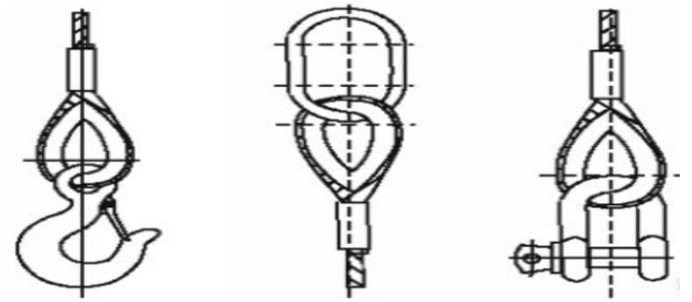

How to use the thimble:

① Select the appropriate thimble according to the wire rope diameter as required, use the same type of chuck to set a certain spacing to tighten the nut, and each rope loop should be locked with at least three chucks and the directions of the chucks should be the same.

② The steel wire rope is braided into the rings at both ends, and a steel sleeve is used to add sealant and press it into a rope sleeve using a sleeve pressing machine.

③ After inserting the ring as needed, insert the end into the 8-shaped or oval aluminum sleeve, add sealant and press it tightly with a press.

④ Common usage of the ring

Inspection standards for thimbles

1. The thimbles should be smooth and flat, without any cracks, flaws, sharp edges and surface roughness defects that may damage the wire rope. The tip of the thimble should fit freely, and the tip should be shortened to half the depth of the groove.

2. The surface of the thimble should be hot-dip galvanized, and the surface should be smooth and flat, without defects such as missed plating, zinc particles, bubbles, cracks, etc. The galvanized layer should have sufficient adhesion strength during normal use.

3. The material of the thimble can be Q235B carbon steel (A3) or 45# high-quality carbon steel.

4. The safety load of the thimble should not be less than 32% of the minimum breaking tension of the wire rope.

5. When in use, the thimble should be selected in accordance with the specifications of the wire rope, and the diameter of the shaft pin used should not be less than twice the diameter of the wire rope.

6. If the thimble is cracked or damaged, it should be scrapped.

7. If the thimble is in contact with the wire rope and there are serious rope marks, it should be scrapped.

Corporate environment

Qualification Certificate

Communication and exchange

FAQ

About Shandong Ningjin Liangyu Hardware Rigging Co., Ltd.

Shandong Ningjin Liangyu Hardware Rigging Co., Ltd., formerly known as Ningjin Baodian Town Hardware Rigging Factory, was established in 1975 and was the only production unit designated by Shandong Machinery Import and Export Corporation for rigging loops at that time.In 1990, Mr. Zhai Liangyu bought out the operating rights of the enterprise and later established the current Liangyu Hardware Rigging Co., Ltd. in Ningjin County, Shandong Province. After 14 years of training and hard work,

What standards are supported for product production?

Our products cover standards from multiple countries around the world, including Japanese standard Type A, British standard BS464, BSS64, European standard BSEN13411-1, European standard ordinary, American standard G-414, G-411, Dutch standard K2, K2B, K3, K3B, K15, German standard DIN6899A, DIN6899B,DIN3090.DIN3091, Australian standard 11381138 open type, national standard WT, national standard heavy-duty ring, etc., and can develop special sizes of irregular ring according to customer's special requirements.

If you are interested in this product, please fill in the following information and submit it to us, we will arrange professionals to contact us as soon as possible!

Related Products

Related Products

Mount Taishan Road, Economic Development Zone, Ningjin County, Shandong Province

Hotline: